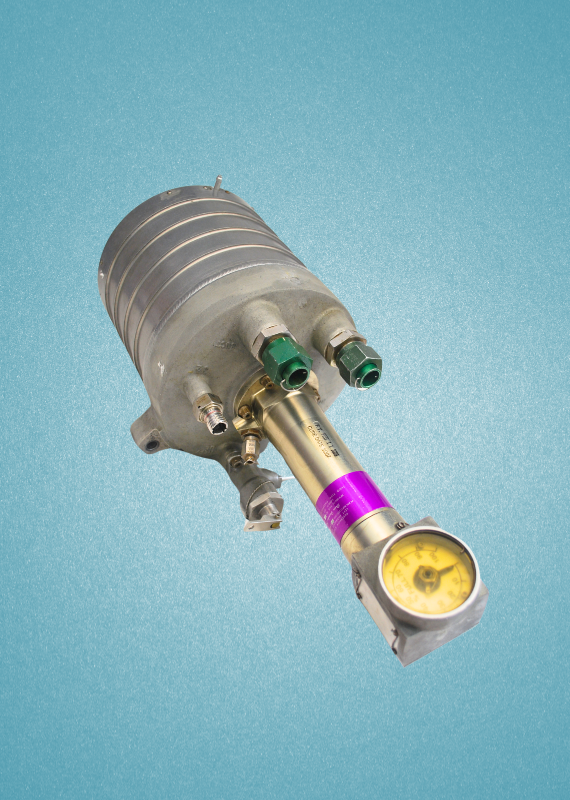

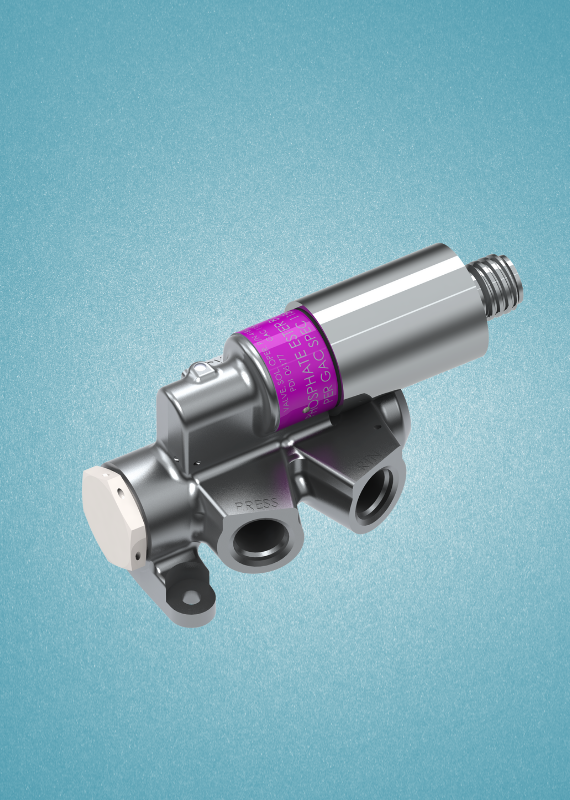

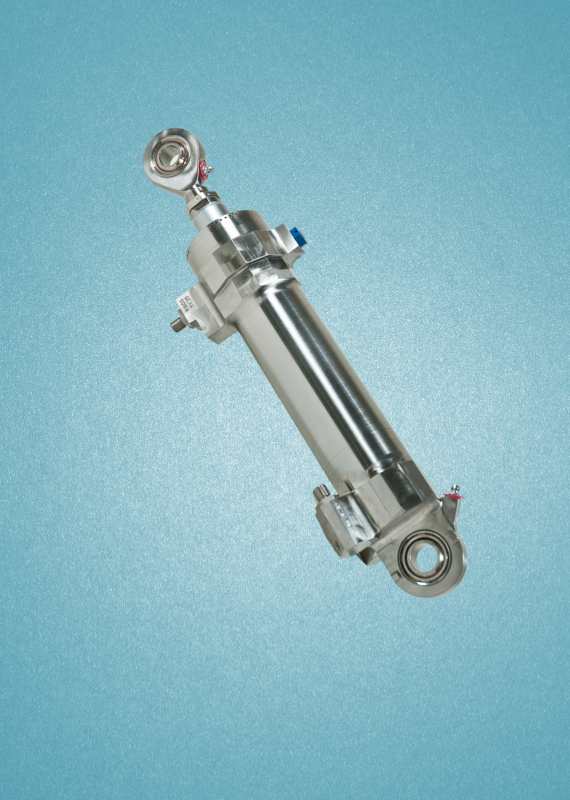

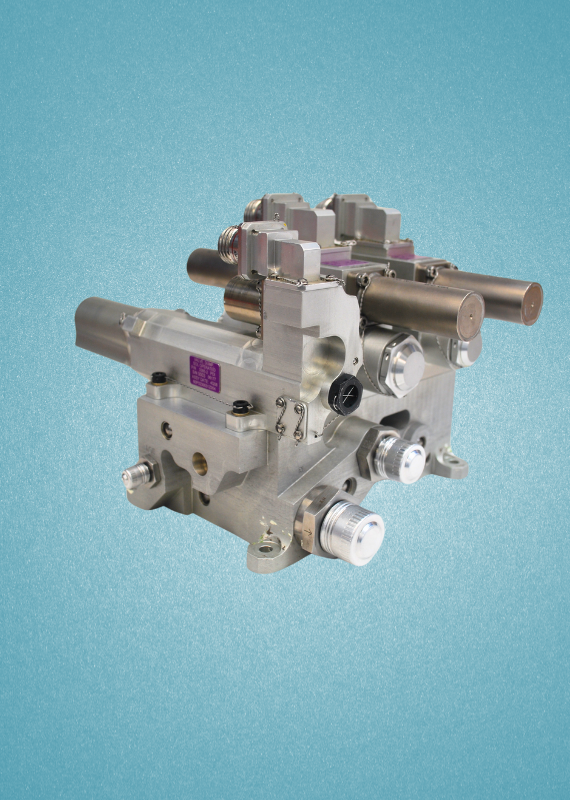

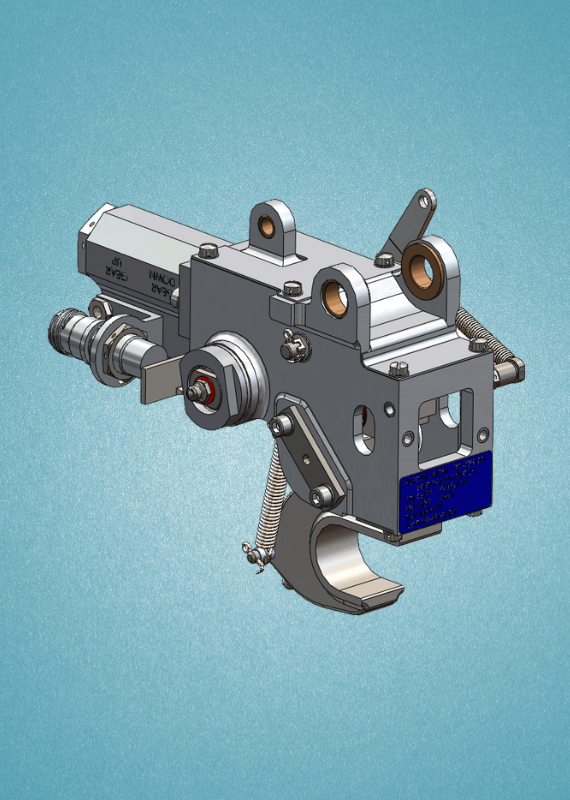

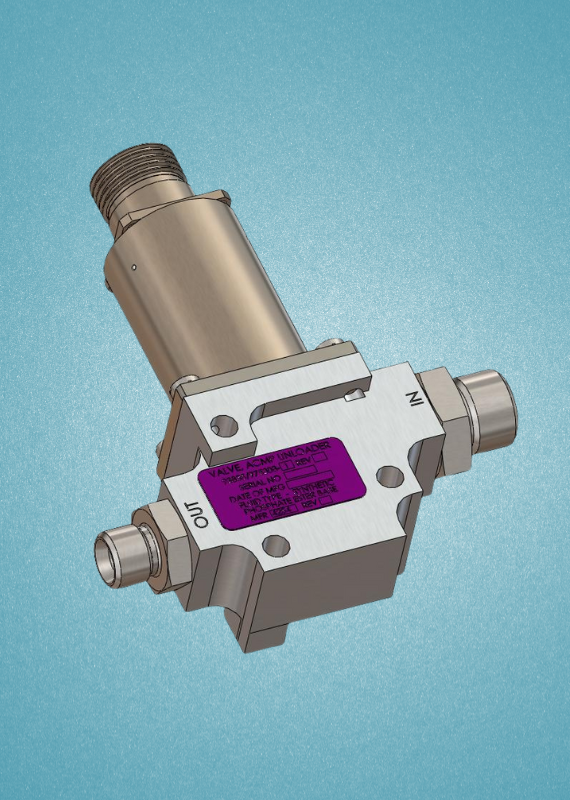

A leading manufacturer of Precision Hydraulic Components for the Aerospace Industry

Eric Saville and Ray Hunt founded PneuDraulics, Inc. (PDI) in the mid-fifties when they recognized the need for a high-quality supplier of aerospace hydraulic system components for the Aerospace Industry. Following a thoughtful growth process fueled by evolving expertise and an ongoing extension of our product line, PDI has become a preeminent player in our industry and has earned a reputation as a highly effective, responsive, and problem-solving organization.

All disciplines—from conceptualization of design and developmental engineering to state-of-the-art manufacturing under rigid quality control standards—are performed in our facility. The result is a fully integrated operation that produces the highest quality aerospace hydraulic system components available today.

As we look to the future, we at PDI stand by our commitment to provide the solutions and hardware that will continue to meet the ever-increasing demands of flight safety and reliability. We enter the new millennium eager to meet these challenges with the teamwork, organization, and skills of all of our employees focused on a single objective: Total and complete customer satisfaction.